Introduction

Motorcyclists’ protective jackets, trousers, one-piece suits, two-piece suits, impact protector ensemble garments and other protective garments (hereinafter: “garments”) are intended to give some amount of protection to riders without significantly reducing the ability of the rider to control the motorcycle. In addition, designed to provide adequate protection against the risks against which they are intended to protect, such as a fall from a motorcycle or another accident. Additional, particular, hazards encountered during a motorcycle accident may include: impact with and abrasion from the riding surface, impacts with the rider’s motorcycle, conflicting vehicles, and other objects. Motorcyclists’ protective garments are not intended to and cannot prevent traumas caused by high-energy impacts, traumas caused by severe forces of bending, twisting, torsion, flexion, or crushing as the result of striking an object, traumas caused by extreme abrasion, traumas caused by extreme movements, or traumas caused by massive penetrations. No protective garments can offer complete protection against all injuries.

The principle of this standard is to define the basic performance requirements considered essential for motorcyclists’ protective garments, in order for them to offer useful, classes of protection to riders according to the risks they may encounter, in the situations described above, during various riding activities and in various riding environments. This standard does not cover risks caused by extreme weather conditions. Where additional protective features are claimed (e.g. high visibility), the assessment of said protective features will be done with reference to the appropriate additional standard. Motorcycling encompasses a diverse range of riders participating in a diverse range of activities. While all motorcyclists face similar fundamental risks when involved in an accident or a fall from a motorcycle, the type and degree of risk or hazard that a motorcyclist will encounter and the class of protection that they will need is closely linked to the riding activity, the riding environment, and the nature of the accident. In addition, because each motorcyclist participates in their chosen riding activity in different ways, within specific riding activities motorcyclists are also exposed to varying levels of risk and, therefore, require varying classes of protection.

The elements that are a part of the fundamental design and functionality of a particular type of motorcyclists’ protective garment, while appropriate and minimally constraining or limiting when used in a specific environment for a specific riding activity, may, on the other hand, present unacceptable constraints and liabilities in other riding environments and for other riding activities, such as increased penalties of weight, decreased range of motion and/or heat stress, and therefore, may not be acceptable for use by all riders during all motorcycle activities. This series of standards has been developed to encompass a large range of motorcycle disciplines and motorcyclists’ activities, each with their own particular risks and appropriate classes of protection, to ensure that the best possible protection of an appropriate type is available for riders during their riding activities. His standard is a part of a series of standards including also EN 17092-2, EN 17092-4, EN 17092-5, and EN 17092-6, which together describe the requirements for motorcyclists’ garments, according to the various classes of protection offered and EN 17092-1, which specifies the test methods to assess the conformity of said garments to the requirements of the applicable product standard of the EN 17092 series.

WHAT ARE PROTECTION CLASSES AND WHAT ARE THEY?

When testing protective clothing for motorcycles, it is divided into different classes depending on its area of use. This means, for example, that a tight, sporty leather suit with large protection zones has losses in the area of comfort and suitability for everyday use according to class AAA and the corresponding requirements.

The 5 classes of protection of EN 17092:2020

EN 17092-2:2020 Class AAA

- Passive and/or active impact protection and passive abrasion protection

EN 17092-3:2020 Class AA

- Passive and/or active impact protection and passive abrasion protection

- Reduced ergonomics and weight

EN 17092-4:2020 Class A

- Passive and/or active impact protection and passive abrasion protection

- Minimum compromises on ergonomics and weight

EN 17092-5:2020 Class B

- Provides protection against abrasion, but has no impact protectors

- Additional impact protectors should be worn on shoulders, elbows and knees to ensure a comprehensive minimum level of protection

EN 17092-6:2020 Class C

- Refers to special suits for motorcycles with impact protectors and no shield, designed only to hold one or more impact protectors in place and serve as underwear or outerwear

- They are intended to provide impact protection at the points where impact protectors are used

- They do not provide comprehensive minimum protection against abrasion or comprehensive minimum protection against impact and must be used in conjunction with Class AAA, AA, A or B protective clothing.

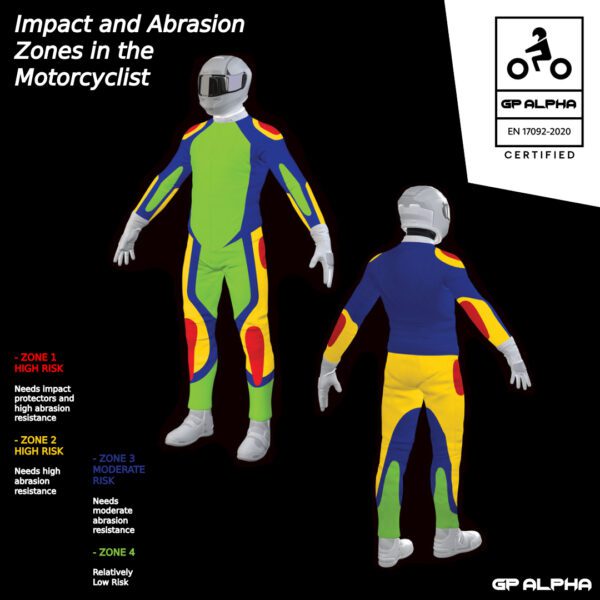

RISK CATEGORIES

The basis for the assessment are the defined risk category areas. To do this, the human body is divided into four zones, the fourth of which is not referenced by the standard, as it is a low-risk zone for the pilot. Risk of injury in the respective parts of the body: joints such as shoulders, elbows, hips and knees are most at risk of injury. The outer sides of the arms and legs and the back are at moderate risk, and the inner sides of the arms, the backs of the legs and the thoracic and abdominal areas are the least susceptible to injury.

Zone 1 – the areas of motorcyclists’ protective garments that have a high risk of damage e.g. impact, abrasion, and tearing.

Zone 2 – the areas of motorcyclists’ protective garments that have a moderate risk of damage e.g. abrasion and tearing.

Zone 3 – the areas of motorcyclists’ protective garments that have a low risk of damage e.g. abrasion and tearing.

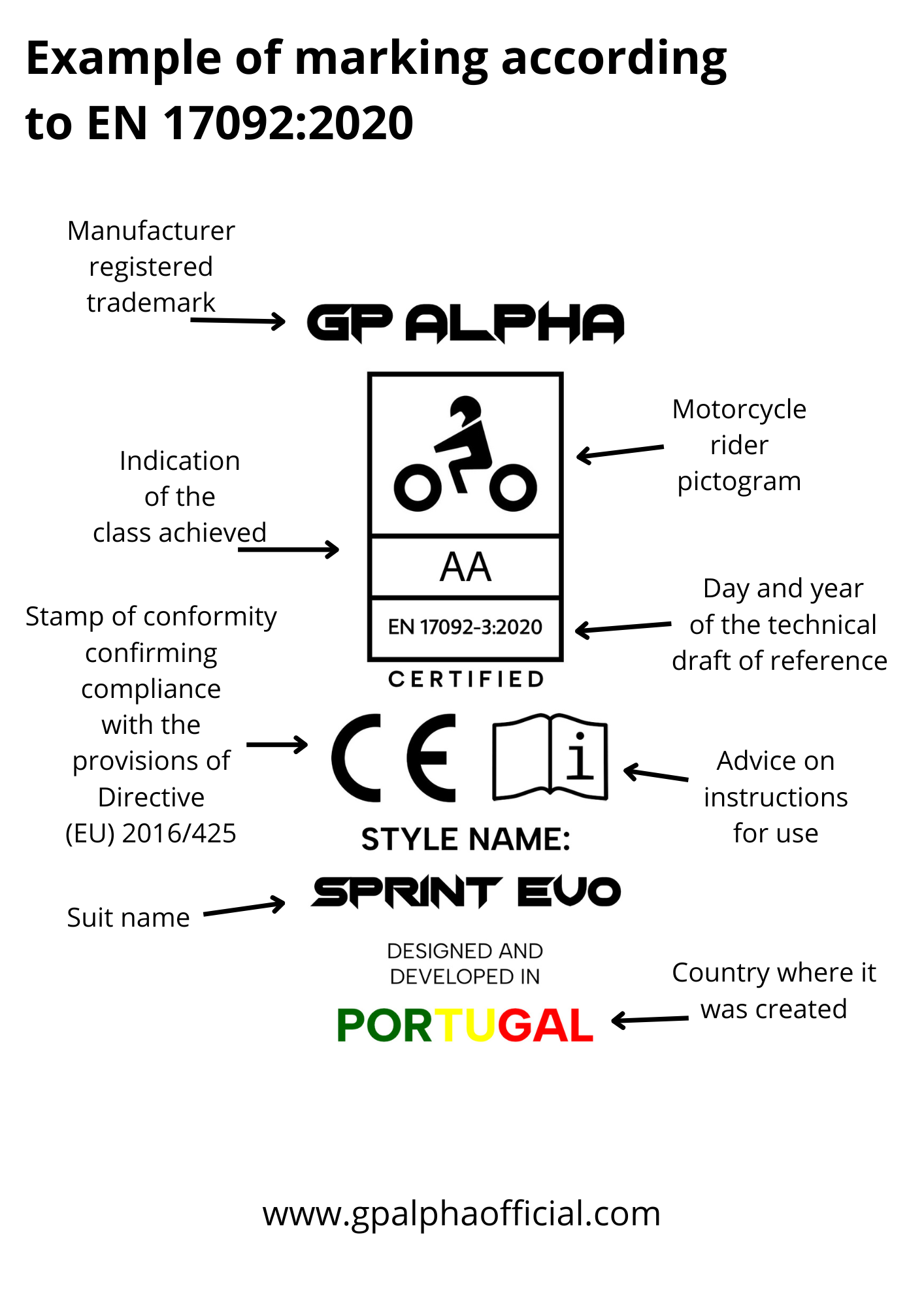

CERTIFICATION OF PERSONAL PROTECTIVE EQUIPMENT

According to Regulation (EU) 2016/425, motorbike protective clothing falls under “Personal Protective Equipment” (PPE) and is tested and certified according to the respective EN standards by an accredited testing institute. If a product from a certain category passes the test procedures of an accredited testing institute, the standard is considered to be fulfilled and the product is considered to be safe for this particular application. This is the prerequisite for the product to be awarded the CE mark (European conformity).

TEST PROCEDURE

1. Visual and tactile testing

The visual and tactile inspection ensures that:

- the protector pocket and adjustment and fastening systems are in the correct position in the garment,

- the protectors are in the correct places on the body and in the correct position in the garment,

- the protector pockets are not too large and do not allow excessive movement of the protectors, and

- protectors attached by other means cannot move excessively.

- The abrasion test procedure is performed on the Darmstadt machine. Here, the material/combinations of materials are tested for abrasion resistance using various rpm settings on the machine.

- Ensures that zones 1 and 2 have safety seams.

- Checks the seam strength under applied forces (class AAA: 12N/mm (zone 1), class A: 6N/mm (zone2)).

- Test of tear strength of leather, textile materials, coated materials and protector pocket material.

- The connecting zipper must withstand a force of 100 N.

- Checking the fastening systems for resistance to 50 N +- 3N circumferential force.